Recent discussions among coatings and specialty chemical leaders confirm that AI adoption is moving beyond curiosity and into disciplined deployment. For companies operating in advanced materials, functional fillers, industrial minerals and critical raw materials, the implications are immediate and strategic. The credibility of this shift lies not in technological enthusiasm, but in operational realism. Competitive advantage rarely comes from a tool alone. It comes from how rigorously information is structured, how quickly learning cycles operate and how consistently insights are applied. AI simply accelerates these dynamics.

The starting point is clear: AI is a data discipline, not a software purchase. Every meaningful deployment begins with structured, accessible and current data. In raw materials and critical minerals businesses, this includes particle size distributions, morphology profiles, mineralogical characterisation, impurity logs, beneficiation response curves, pilot plant recovery data, reagent consumption records, customer qualification trials and regulatory compliance screening. When these datasets sit fragmented across spreadsheets, PDFs, notebooks or disconnected systems, insight remains stranded capital. The most commercially valuable data is not the archive of past work, but the experiments being conducted today. Failure to capture current testwork, qualification outcomes or process adjustments in structured form is effectively forfeiting future advantage.

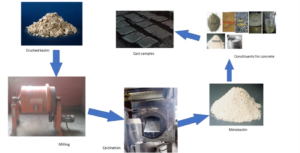

AI does not replace materials scientists, mineral processors or formulation chemists; it compresses iteration cycles. In advanced materials markets, the bottleneck is rarely geology. It is qualification time, experimental loops, specification alignment, regulatory review and supply chain coordination. AI accelerates formulation screening, enhances design-of- experiments modelling, identifies non-obvious variable interactions and narrows the range of viable pathways more quickly. For functional fillers such as kaolin, silica, talc, alumina trihydrate, calcium carbonate, engineered quartz and rare earth-based additives, this translates into faster alignment between material properties and end-use performance, improved modelling of dispersion behaviour in polymers and coatings, quicker optimisation of beneficiation flowsheets and shorter scale-up timelines from laboratory to commercial 2 production. In critical materials markets — including high purity quartz for solar glass, specialty kaolin for ceramics and coatings, engineered silica for elastomers and rare earth separations — speed of iteration becomes a defining competitive variable. The technical challenges remain largely the same; the difference lies in how quickly they are solved.

The intellectual property dimension is equally significant. No serious materials company is exposing proprietary R&D or beneficiation data to public AI platforms. Proper deployment requires controlled private environments, encryption keys owned internally and strict segregation between public and confidential datasets. A model trained on decades of beneficiation curves, impurity correlations, recovery factors, surface modification trials or customer performance feedback becomes intellectual property. For a kaolin or silica producer, a system trained on brightness versus iron response curves, dispersion behaviour across different end uses or rare earth mineralogy versus acid consumption effectively embeds institutional knowledge into software. As basic specifications and standard flowsheets become globally accessible, proprietary structured data becomes the true competitive moat.

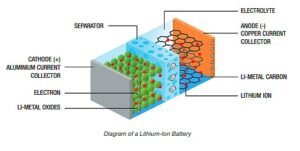

In the critical minerals sector, AI also carries regulatory and geopolitical importance. Export controls, environmental permitting frameworks, REACH updates, critical raw materials legislation and ESG reporting requirements are increasingly dynamic. AI-enabled systems can flag at-risk products, suggest compliant substitutions, monitor supply chain exposure and assess supplier risk in real time. For rare earths, battery materials, high purity quartz and other energy transition inputs, regulatory agility increasingly determines market access. Early awareness and rapid response become forms of strategic leverage.

AI is also reshaping talent dynamics. Advanced materials industries have long depended on tacit knowledge held by experienced chemists, mineral specialists and process engineers. As generational transitions occur, structured digital knowledge systems become critical. AI- enabled environments shorten onboarding cycles, improve access to institutional memory and reduce knowledge loss from retirement or turnover. Younger technical professionals expect searchable, digital-first laboratories rather than paper-dependent systems. AI does not replace expertise; it amplifies it and preserves it.

The competitive reality is changing. Basic formulations, generic mineral specifications and standard process descriptions are increasingly transparent and widely available. Sustainable advantage now depends on proprietary performance datasets, rapid learning cycles, regulatory responsiveness and the ability to move efficiently from concept to qualified product. AI amplifies organisational discipline. Companies that digitise early, protect intellectual property carefully and integrate AI into formulation, sourcing and compliance workflows will compress development cycles and strengthen defensibility. Those that delay risk competing on commoditised knowledge rather than proprietary insight.

The practical path forward is disciplined and phased. Capture current experimental and application data in structured form. Secure proprietary datasets within controlled digital environments. Pilot targeted use cases with measurable commercial impact. Develop internal champions who bridge technical and digital capability. Expand adoption incrementally as value becomes demonstrable. Perfection is not required at the outset; progress is.

The broader shift is structural. The coatings industry is moving from AI exploration to competitive acceleration, and the same transition is underway in industrial minerals and critical materials. Artificial intelligence in advanced materials is not speculative. It is an operational acceleration mechanism embedded in laboratory systems, sourcing workflows, regulatory monitoring and process optimisation. The companies that prevail will not be those with the flashiest tools, but those that structured their data early, protected their intellectual property, integrated domain expertise with digital systems and relentlessly compressed decision cycles. For raw materials, functional fillers and critical minerals, AI is no longer novelty. It is infrastructure.

Note: Inspired by themes emerging from “Inside the AI Shift in Coatings: Insights from the CTT Summit Keynote Panel” (PCI Editorial Staff), this note explores the implications for advanced materials, functional fillers and critical minerals.